I've seen several comments around the internet recently asking about functional HO Scale spring switches. LMRC club member David Willoughby was good enough to go dig up some photos and write the following document about the La Mesa Model Railroad Club's spring switch installations.

SPRING SWITCHES

on the

TEHACHAPI PASS EXHIBIT

by David Willoughby

Recently, I have received a couple of requests for information about the La Mesa Model Railroad Club's spring switches. First, I'll briefly describe our switch construction methods in general, and the linkage we use for regular switches between the motor and the points.

OUR SWITCHES ("TURNOUTS")

Nearly all of our 750 or so switches (or "turnouts," as model railroaders and railroad civil engineers call them) are hand-laid on wooden ties. Our methods were developed over five decades ago, and were based on an article in Model Railroader around 1955 by author Robert F. Cushman. Initially, all frogs and points were made by hand from suitable nickel-silver rail; usually we now use cast frogs and points, some or all of which are available from Detail West.

One way our switches differ from many other model switches is that there are gaps between the frogs and closure rails so that the points and closure rails can be electrically connected to the adjacent stock rails. This makes the gap between the stock rail and the open point as close to scale as NMRA wheel standards will allow, without running the risk of a short circuit if the back of a wheel brushes against a the point. These days, this characteristic is sometimes called "DCC-friendly" because it minimizes the likelihood of a short circuit that can shut down a DCC booster, stopping every engine in the section it powers.

We use rail joiners on the ends of the closure rails loosely fitted to the heels of the points as a hinge, and connect them to an insulated throw bar using 00-90 screws, which are left loose enough that they don't bind. The throw bar, which is made of 1/16" thick phenolic, rides in the space between two adjacent ties. (These are usually the head-block ties, through SP standards specified the use of only one head-block tie for hand thrown switches.) In the center of the throw bar there is a hole for a piece of 0.030" dia. steel piano to link it to a switch motor. A hole through the ballast board and roadbed below the throw bar is widened into a slot to allow a wire from the motor linkage below the roadbed to move the points. The first photo attached shows what one of these switches looks; this one is a spring switch at the east end of the center siding at Bena.

|

| "Normal" PFM Switch Motor installation. - D.F. Willoughby photo |

Over 35 years ago, we standardized on PFM/Fulgurex switch motors, which were among the first motors available when twin-coil solenoid switch machines were still nearly universal in model railroading. (The PFM motors are no longer generally available in the U.S.) They have a plastic throw bar with holes at either end for a wire to link the points to the motor assembly, and cutoff contacts to stop the motor at the end of its travel. Our standard installation has the motor screwed to a small piece of 3/8" birch plywood with a couple of slots or oversize holes that slip over studs screwed into the bottom of the roadbed. We also put a Molex ® connector on the wires to the motor for motor power, and for the frog and auxiliary contacts. The connector and wing nuts on the studs allow a motor to be swapped out for repairs without any tools or soldering. The oversize holes allow the motor position to be fine-tuned so that the tension on the points is approximately equal in both positions.

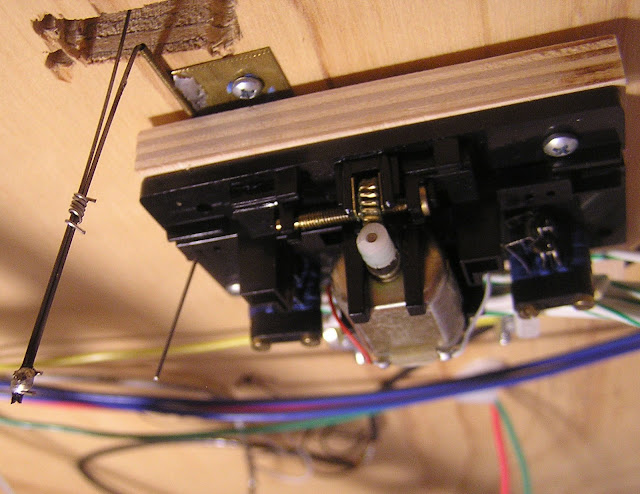

To link the motor to the point throw bar, we fabricate a "Z-link assembly" using a piece of 1/32" I.D. brass tuning soldered to a small brass plate that is then screwed to the bottom of the roadbed. A piece of 0.030" steel piano wire is slipped through the tubing and bent upward at one end and downward at the other, forming a "Z." The lower end goes down into the throw bar in the motor and the upper end extends upward through the hole in the throw bar that connects the points. The second photo attached shows one of these standard installations.

To link the motor to the point throw bar, we fabricate a "Z-link assembly" using a piece of 1/32" I.D. brass tuning soldered to a small brass plate that is then screwed to the bottom of the roadbed. A piece of 0.030" steel piano wire is slipped through the tubing and bent upward at one end and downward at the other, forming a "Z." The lower end goes down into the throw bar in the motor and the upper end extends upward through the hole in the throw bar that connects the points. The second photo attached shows one of these standard installations.

SPRING SWITCHES

A clip starting at 8:00 of Jason demonstrating the operation of Bena's spring switch. - TSG Multimedia's Tehachapi Pass Tour video

|

| East Bena, center siding spring switch. - D.F. Willoughby photo. |

|

| Spring switch motor installation at Tehachapi. - D.F. Willoughby photo |

I've attached two photos showing these linkages at two different locations. There is one minor difference between these two installations. For the earlier one, the coil of wire for adjusting the tension is soldered in place. This makes later adjustments rather difficult. On the second one, the adjustment coil is still movable, but the ends of the U-link and the phosphor-bronze spring have been soldered together, with a large enough blob of solder at the bottom to keep the ends parallel and keep the coiled piece of wire from falling off. Once the spring wire and the U-link are soldered together, there's no need for the bend in the wire to keep the spring wire from falling through the throw bar between the points, and the only way to remove the throw bar is to loosen the switch motor and unscrew the U-link from the roadbed to make it possible to drop the linkage assembly.

The frog sections of most of our switches are less than about two inches long, with gaps at both ends. We generally leave the frogs of our spring switches unpowered. Large steam engines, and diesels that pick up from both rails on all axles have no problem with them at all. Only the smallest steam engines and tenders lose power briefly when passing over the longer No. 9 frogs. If this is a concern, an electronic frog circuit such as Tam Valley's Frog Juicer can be used to power the frog.

There are occasional derailments when there is not enough downward force on a wheelset trailing through a spring switch to push the closed point out of the way. Our car standards specify minimal slack in bolster screws and most of our freight cars use rigid frame trucks and lifting one wheel off the rail wheel lifts the whole truck frame and starts to tilt the car. Cars with loose trucks that are loosely sprung or fully equalized may derail more easily on spring switches, as it takes less force to lift an axle off the rail trying to push a closed point over. Pilot trucks on steam locomotives sometimes require increased downward spring tension, or a small weight glued onto them, to provide enough downward pressure. Two-wheeled pilot trucks seem to be particularly prone to this kind of derailment.

Spring switches can be a bit of a maintenance headache. Problems arise when dirt, dust, ballast or other residue collects under and around the point throw bar. This increases its resistance to movement so that the gentle pressure applied by the phosphor-bronze spring wire is no longer sufficient to reliably seat the point against the stock rail. This residue can often by dislodged by moving the points back and forth vigorously with a finger. If that doesn't work, try removing it with a pick, or by blowing it out using a straw or an aerosol can of air. If the contamination is under the throw bar, it may be necessary to remove the points and the throw bar to clean it out. Tight clearance around the throw bar will make it particularly likely to be sensitive to contamination, and can only be fixed by removing the the points, and the throw bar and carving out more clearance with a knife or motor tool.

So far, we have installed about ten spring switches on the Tehachapi Pass exhibit. Several are used in places that only see service during formal operating sessions that take place about a half-dozen times each year. But the ones on the reverse loops are used daily when the railroad is operated for the public and trains have to go through them at each end of every trip over the mainline. Their convenience far outweighs the disadvantage of their occasional need for maintenance.

In Closing

Thanks to David Willoughby for writing up what the club has done to make our spring switches work. Most of my experience with the pilot or trailing wheels derailing are usually caused with the leading wheelset trailing through the switch, and trying to actuate the points to move with very little lever moment. However, a properly adjusted spring switch should be able to handle the club's minimum weighted cars (spine intermodal cars and cars with very high CG counts, such as Athearn 65ft Mill Gondolas, only weighing around 2.5 ounces.) It's pretty interesting to watch a train going over the spring switches and hearing the points snap back to "normal" route under middle of each car going by.

Jason Hill

No comments:

Post a Comment

Please identify yourself at the end of your message. Please keep comments relevant to the post or questions to me directly.

All comments are moderated and must be approved, so give me a bit of time to approve them.

No random solicitation in comments. Spamming and phishing comments will be deleted or not allowed to post.