Well, this Part 2 articles' been a long time coming, here's the link back to Part 1.

|

| Let's get building some stacks of Racks! |

I'm going to be using the actual OwlMtModels instructions for the 1924 Blackburn Racks in this post. Interspersed in between the instruction pages will be my additional commentary and photos of constructing an actual rack. Hopefully, this will help anyone building this kit and provide some perspective and alternative steps in construction, including some warnings about pitfalls I've seen in building 10+ of these kits.

I'm going to start by laying out all the parts and showing them below. The majority of the parts are injection molded in a brown-red, roughly SP Freight Car Red color, with the A-frame panels in light gray, which will make the board weathering easier on that section.

The pre-assembly work I do covers pre-weathering the interior of all the FCR wood parts and the A-frame sections.

|

| Interior wooden parts pre-weathered before assembly. |

Depending on the age of the car the wood color could be anything from natural Douglas fir to gray-silvered wood with dirt ground into the wood grain. The H-shaped "Diaphragm" steel plates could be either raw iron/steel or painted, to some form of rust/scraped by falling and dumping beets. - Period photos don't really show which they should be, certainly in-service photos don't show and they are all in black and white on top of that.

|

| Pre-weathering door interiors and cleaning back side of locking bars. |

The inside of the locking bars on the door sprues are cleaned off of the wood paint so they can be glued cleanly to the frame in the later assembly.

.jpg) |

| Interior unweathered and top of A-Frame Slope Sheets weathered before assembly. |

I'm not too worried about the interior or underside of the A-frame panels being 'weathered' as they really won't be visible when the rack is assembled and placed on the F-50-series flat car.

On page 2 of the instructions, the grab iron and tie-rod holes are called out to be pre-drilled. I prefer to do this at this point, as gripping the assembled bodies later to do later drilling should be minimized. The racks are surprisingly strong, but even so rough handling will cause damage.

I cut the ends out of the sprue before I took this photo, so that I could airbrush the steel diaphragms with FCR or raw steel colors. The ends have their interiors painted with raw weathered wood, along with the rest of the interior parts of the rack.

The basic assembly starts with the frame and building the mating faces for the future operating levers which form the "B-end" of the rack. Note that the B-end of the rack is actually the A-end of the flatcar. This is so the workers climbing have space on the end of the car to actuate the operating levers and trainmen to tie or release the brake wheel, and don't get in the way of the other.

One of the trickiest parts of the build starts at the bottom of Page 4, with the assembly of the rack frame and the A-frame panels. If these three parts were to be assembled alone, there wouldn't be much problem. However, the Blackburn racks need three 'diaphragms' or bulkheads installed through the A-frame panels before anything can be glued. This would require 4-5 hands to hold everything in alignment. Instead of having 5 hands, I found that using a little bit of masking tape works great to hold the A-frame panels with a hinge-line along the outer edge while I place the diaphragms in to the center opening.

Page 5

The diagrams cover the technique of assembling the A-frame and diaphragms pretty well.

Photos of Step 7.

.jpg) |

| A-Frame Slopes taped to frame while Diaphragms being dropped into place. This needs 4 hands, or taping to help hold all the parts. |

However, I will say that the physical process of making the parts all line up at the same time without holding them in some sort of zero-gravity magnet vise does require a bit of patience and timing.

.jpg) |

| Diaphragms in place, A-Frame Sheets rotate down into position. |

Once the diaphragms are in place with the triangle A-frame supports below the A-frame panels, the panels can be allowed to close up. Notice the the B-end of the frame is to the left in the photo above and the diaphragms are not symmetrical, so the cross plate is offset where the notch in the top and the post notches in the lower side edges

.jpg) |

| Closing up the A-frame around the diaphragms, using the masking tape 'hinges' as extra hands. |

To 'lock' everything in place, I place two more small strips of tape over the top of the A-frame peak, holding the panels together. Tamiya liquid plastic glue now works great to work around the interior underside of the A-frame to weld all the parts together.

.jpg) |

| An underside view of the A-frame with tape during assembly. |

Not much more to see here, although I like to use the access to the underside to apply the liquid plastic cement to the three joints of the A-frame and frame, and along the peak joint, and also to the diaphragm center plate to frame joints.

|

| A little out of order, but a short showing the underside with completed diagonal A-frame end beams. |

At some point nearing completion of the Blackburn rack, the two diagonal end braces under the A-frame can be added. I like to wait until the rack is nearly done to do these. They are not visible from any angles except looking in through the end slats, so there is a good question as to if they're really worth putting in. I've found them to be fragile if I forget about them and wrap my fingers into the under side of the A-frame when picking up the rack and not thinking. If they break, then I don't worry about them anymore.

I like to assemble the grabs and put them on before gluing the ends to the rack... but the photos below show that I forgot them on this car until later, so it is out-of-order to what the instructions show.

I bend all the needed grabs that will be installed on the sprue bending jig. I like using a good set of needle nose pliers (Leatherman tool), starting with a 90 degree bend about 0.06-0.07" from the end of the 0.012" Phosphor-Bronze wire, then placing the grab on the jig, and using my finger, usually my thumb to bend the second 90 degree bend. Removing the grab and cutting off the grab about 0.06-0.07" from the second bend.

.jpg) |

| Bending jig for grab irons. |

I bend all the needed grabs that will be installed on the sprue bending jig. I like using a good set of needle nose pliers (Leatherman tool), starting with a 90 degree bend about 0.06-0.07" from the end of the 0.012" Phosphor-Bronze wire, then placing the grab on the jig, and using my finger, usually my thumb to bend the second 90 degree bend. Removing the grab and cutting off the grab about 0.06-0.07" from the second bend.

-2.tif) |

| Grab irons and spacing tool. |

Now that the grabs are bent, I remove the spacing tool from the door sprue. The wide part of the spacing tool is used for the ladder grabs and the right-side horizontal grab, keeping the grabs from going into the end too far. The narrow end is used to space the center horizontal grab on each side of the center post.

At this point, with the grabs installed on the ends, now it's time to glue the ends to the rack assembly. The end with the notches in the posts will go on the B-end of the rack, which will have the levers installed later.

Time to work on the doors now. Remember that before we started the assembly, the doors' interiors were painted with wood weathering, and the inside of the locking rods were cleaned off.

The details of installation of the doors is pretty simple. The doors fill the space between the diaphragms, hooking onto the lower longitudinal rod and gluing onto the base frame with the detail locking bar.

A little bit of liquid glue will work on the sides of the door to the posts and along the bottom where the locking bar rests on the frame.

.jpg) |

| Doors installed - high angle |

A couple views of the rack at this point.

.jpg) |

| Doors installed - lower angle |

Time to move on to applying the upper sides.

The two upper sides are keyed at the center diaphragm where the post is offset, so if it doesn't fit right on the first dry fit, then try swapping sides.

.jpg) |

| Upper Sides in place with weathered interior. |

At this point the whole rack structure should be getting very sturdy.

Time to move on to the finishing steps, adding the last of the grab irons and operating levers to the rack.

The last of the grabs needed are outside the end posts, which can't be center spotted during the injection molding process, so I'll have to mark the locations with my carbide scribe. Thankfully at this point in the assembly the body is quite strong and can be layed on its side. I usually will pre-bend the grabs and work from a hole just above and below the existing grabs that are already crossing inside the post, so I don't them with my drill bit this time.

The Operating Levers are easily cut off the sprue and mounted on the B-end of the rack. The lower end of the lever and operating rod should line up with the door clip and hide the joint well enough.

The B-end alignment stake plate should be glued in place. This was molded separately so that any length discrepency with the F-50-series deck end stake pockets don't cause a problem. This may mean that the rack will fit better on one car than another, so you may wish to mark on the underside of the A-frame what cars the rack fits on best.

|

| Sides of rack distressed, mostly upper sides and door vertical boards. |

If you want to distress the exterior of any of the boards, this is the best time to do it. Perhaps rough sanding sticks, 120 grit or so, or by hand with the carbide scribe.

I paint my racks with SP FCR by airbrush. The interior of the rack's weathering is protected by crumpled up toilet paper or Kleenx tissue paper acting as a mask. A gloss-coat is applied, at least around the areas where the decals will need to go.

|

| B-1374 and B-1486 end stenciling |

I decided to model racks B-1374 and 1486 with vertical end numbers.

|

| B-1135 on SP 43745 with horizontal end lettering. |

End B-number horizontal or vertical? Some photos show the rack number one way, some show it the other... occationally a car won't seem to have a clear number painted on at all, perhaps it has flaked off, worn off, or is covered with dirt.

Access to underside of rack...

|

| Earlier Blackburn Sugar Beet Rack Unloading - Note no end reporting marks on the rack. - Pat Bray collection, John Signor collection |

It seems that some racks had one of the lower end boards cut away, which would make a hole big enough for repair and inspection under the rack without removing it from the car... or likewise, if the rack was removed from the car, I wouldn't want to trust any form of saw-horses to keep the rack up while I go poking around with the structure of 7-odd tons of rack above me!

|

| B-1135 with access hole cut in the A-end and a small board covering it to keep any random hobo out. |

|

| Rack reporting marks "B-1390" in the 'right position' option seen in most photos. |

This photo is VERY interesting as it is taken around 1942, or a few years later judging by the tare date on the racks. The Rack 1823 is the highest rack number I've yet seen! It certainly is a 1928 rebuilt rack with 4-boards, showing the 'shortened' version.

The rack also has a stencil "OXNARD" which suggests that the racks were assigned to a particular sugar beet plant, in this case the American Beet Sugar Company. Note the rack on the right has a routing card on the vertical post, just left of the center of the car. The B-1823 has a routing card on the far right door vertical board. Also, the "B-1823" is shifted to the 'left position', which is one of the less common positions from the other photos I've seen. Was this a pre-1946 paint standard? I don't know, we need to see more photos.

The rack also has a stencil "OXNARD" which suggests that the racks were assigned to a particular sugar beet plant, in this case the American Beet Sugar Company. Note the rack on the right has a routing card on the vertical post, just left of the center of the car. The B-1823 has a routing card on the far right door vertical board. Also, the "B-1823" is shifted to the 'left position', which is one of the less common positions from the other photos I've seen. Was this a pre-1946 paint standard? I don't know, we need to see more photos.

Both SP 42689, an F-50-9 with B-1823 (left) & 41310 an F-50-5 (right) have missing or heavily damaged deck boards. I wonder if these cars were chosen for beet rack service during the depression or war to avoid re-decking the cars, just to put the racks on them? Also notice that these cars still are wearing their original pre-1928 lettering scheme, with the center reporting mark numbers on the car's side frame. I really like studying this photo, I think the next pair of F-50-series cars I build with racks will replicate these two cars!

Car Assignments

While SP certainly supplied most of the cars for Blackburn beet rack assignments, the racks were always designed for a standard flatcar which was at least 10-15 years older than the rack design. It is pretty clear this is so there was always a ready supply of cars to cover the "beet rushes" during harvest season.

The SP had a vast fleet of several thousand flatcars, but their fleet was also needed for all sorts of other loads besides Blackburns, so the older F-50-series cars would generally start to stay around home rails, but subsidiary cars would also be drawn into service if they were available.

Texas Lines

Extra cars could be pulled from T&NO and sent to the Pacific Lines, while this may have mostly applied to the older WWI-built F-40-6/7 and F-50-6/7 truss rod cars, it probably also applied to the F-50-8/9s by WWII and after, to the end of Blackburn use.

Pacific Electric

|

| PE 3669 with a Blackburn beet rack, a white piece of paper's attached to the door as a routing card. |

The Pacific Electric fleet of F-50-series cars was mostly absorbed into the SP fleet in three groups, 1940, 1948 and finally in 1951. As each batch of cars was transferred, I'm sure the reporting marks weren't immediately re-stenciled. The cars while still in PE marks, they could be put into Blackburn service by the SP. I'm sure from 1948-1951 the remaining PE cars, like PE 3669, would have become more and more at the beck and call of SP traffic department and PE's agents would be allowed to ask for any suitable SP car during the period.

I doubt that NWP cars would have been assigned to Blackburn loading on the SP, at least until the SP bought out the ATSF's share. I believe there always would have been plenty of lumber loading off the NWP to keep their cars, and hundreds of SP cars busy in that service, but that's another blog post altogether.

In Closing

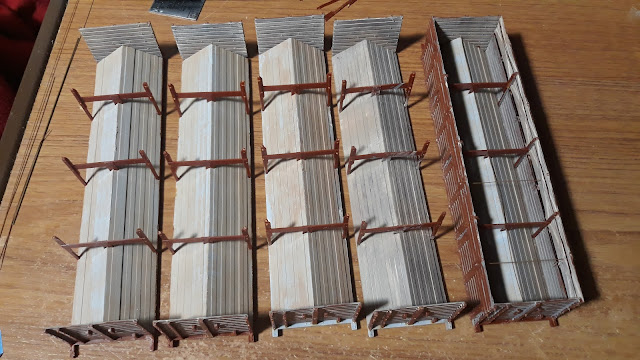

|

| String of empty OwlMtModels Blackburns move to their next assignment for loading. |

The Blackburn beet racks really are an interesting model to have available for loading Owl Mountain Model F-50-series flatcars.

Jason Hill

Related Articles

OwlMtModels Blackburn Sugar Beet Racks - Link to sales page (and combo kits with F-50-series flatcar)

OwlMtModels F-50-series Flatcars - Link to F-50-5/8/9/10/12 page

References

Direct links to Ventura Museum photos

1928 4-board Blackburn racks with high B-number

https://photographs.venturamuseum.org/items/show/3173?fbclid=IwAR0Xa-Z20Bi6jba0j6KW6T2CdDX0weGBkJ6Onn--MgiWBtuqv-HcgDS4JhQ

Ventura Beet Dump

https://photographs.venturamuseum.org/items/show/3178?fbclid=IwAR1pXnEpzcIBasQcAW37CdJoip0BBE-1nG80nekC1PygJmTdy7vokYsj2RQ

%202020-03-02B%20(Final)01B.jpg)

.jpg)

%202020-03-02B%20(Final)02C.jpg)

.jpg)

%202020-03-02B%20(Final)03.jpg)

%202020-03-02B%20(Final)04B.jpg)

%202020-03-02C%20(Final)05D.jpg)

%202020-03-02C%20(Final)06.jpg)

%202020-03-02C%20(Final)07B.jpg)

%202020-03-02C%20(Final)08.jpg)

.jpg)

%202020-03-02C%20(Final)09C.jpg)

.jpg)

%202020-03-02C%20(Final)10B.jpg)

%202020-03-02C%20(Final)11A.jpg)

%202020-03-02C%20(Final)12B.jpg)

2.jpg)

No comments:

Post a Comment

Please identify yourself at the end of your message. Please keep comments relevant to the post or questions to me directly.

All comments are moderated and must be approved, so give me a bit of time to approve them.

No random solicitation in comments. Spamming and phishing comments will be deleted or not allowed to post.