You'll notice my excitement as they were being delivered slowly fading as the problems continued over the years. Towards the end of this page, I'm adding my new experiences since 2008, when this page was taken off of my old website.

Intermountain AC Cabfowards are Coming!!!

|

| My first Intermountain SP AC-12 Mk-1 No.4279 at Caliente, CA on the La Mesa Club's Tehachapi Pass Layout, April 2007 |

NEW PROJECT!

April 8, 2007

I am writing this article here on my page dedicated to what it will take to get these monsters into service. This will involve painting, weathering, DCC programing of CVs and lubrication of the various parts on the engine. Between the various members of the La Mesa Club we have about 10-12 of these new AC's coming in the mail with DCC/Sound installed by the end of March. I'm very excited to see how they do on the Tehachapi Pass layout with the 2.34% grades.

I decided to purchase this first model as a non-DCC model and install one of the new SoundTraxx Tsunami Cabfoward chips in it myself. Out of the box it looks beautiful! The engine alone weighs in at 26 ounces. I gave the first thing I did was set the engine on my old test track at home and made sure that the engine moves under analog control. No problem here.

The next step was to change the engine number from the factor available #4287. That number's already taken at the club, so I started looking for a new number to decal my model as. I decided to finish it as the 4279, as it looked in Colton, CA on March 6, 1949.

I used San Juan Decals (out-of-production 2016). This was my first experience working with decals from this manufacturer. I must say that they are thinnest decals I've ever worked with. I ruined several "4"s before I went back to the 'old' "right" way to decal by laying the backing and the decal onto the model and sliding the decal off onto the model. The decals are so thin they will fold up or tear being transferred on a #11 Xacto blade.

I did a light coat of weathering on the drivers and side rods, just ot lighten up the color so the engine was not riding on a black hole of shadows under the boiler. I followed up with some light lubrication of oil on the side rod joints and driver bearings on the frame. The engines are shipped with these joints dry, so that excess oil doesn't spread around on the inside of the clear display/protective packaging. So doing this BEFORE running or evening breaking in the engine is HIGHLY recommended by the manufacturer.

ADDED NOTE: from later experience, check the gauge of all the wheelsets on the engine and tender. Regauge if needed and place a dab of ACC or LockTight on the press fit joints BEFORE adding lubrication. I just slipped the quartering on two drivers after regauging. It's OK now, but I'll do better next time. (Note, this was a major problem of the Mk-1s having the drivers slip quartering.)

The next day I went down to the Tehachapi Pass model and ran the engine from Ilmon to Tunnel 8 (above Cliff) and back to get a feel for the engine in analog operation. After which I opened the tender and made a electrical drawing of the analog circuit board and which wires went to what pins connecting to the engine.

Once this was done, it was an easy 5 minute job to tin the decoder leads and swap over the wiring to DCC. I also hooked up the small speaker I had on hand. The engine is designed for two 1" diameter speakers and even has an engineered in chamber to hold them. I will swap my little speaker for two 1" ones when I have the chance.

Programming of the SoundTraxx Tsunami chip took only about three minutes to do. Just setting the long address (engine #) and the other club standard options to be able to run the engine.

I test ran the engine and started playing with the sound features. Last night I was able to get the engine to drift and work as it starts a train. This was easily done with the downloadable instructions on the SoundTraxx website.

Photos

|

| Left side of SP 4279 on Main Track at Caliente, CA. in 2007 |

|

| Light helper SP 4279 drifing westward into Caliente, CA. |

|

| Right side of SP 4279 running light west on the Main Track at Caliente, CA in 2007. |

Problems

The first thing I noticed was that the engine didn't move very fast, even in analog, it just topped out at about 2/3 throttle and wouldn't go any faster. normally this would not be an issue, but it topped out at just 25 MPH!!!

I opened the engine today and looked at the motor. I marked the flywheel and counted the turns of the motor for one turn of the drivers. The engine has a 47:1 gear ratio! That explains the great low end speed.... and why I can't do more than 25 MPH. David Willoughby and I figured out that the engine must have a motor with about 7500-8000 RPM max at 12V to get that speed. We figure that to make 60 MPH, the rated speed for an AC-7 thru -12 class engine, it would need a 16K RPM motor.

Tomorrow I will call NWSL to see about a 16K RPM motor that will fit inside the boiler weights of the engine.

The engine also seemed to not like certain parts of the layouts track work. I checked the wheel gauge and found that the drivers were VERY tight in gauge. I will work on regauging the engine tonight or tomorrow before any more testing.

Lastly, the headlight seemed a little on the greenish side of yellow, so I may replace the factory LED with my standard 3.0V Mini-Tronics bulb and resistor the next time I open the engine.

Other Updates

Continuing the effort to get the engine finished, I added a pair of crewmen ot the engine when I had it apart looking at the motor. I painted out the RED class lamps on the front of hte engine with Reefer Gray, to look like they were off. I also did some finish weathering to bring the engine closer to the photograph of the engine I have. I added the engine number to the round front number plate above the headlight.

April 9, 2007

Regauged the drivers today and didn't put a drop of CA on the joints of hte wheels and axles! BAD IDEA! The engine moved about 12" and slipped the quartering of the first, second, and forth drivers of the front engine. It took about 20 minutes to get the wheels regauged and quartered.... Next time I'll know how to do that. Intermountain if you're reading this, PLEASE check the gauge on these engines coming from your manufacturer on the next run. (Note: These issues were fixed on the Mk-2s)

I also finished resetting the CVs on the Tsunami so that the train indicators light up now. I think the next time I have the engine apart I will change the headlight to a 3.0V bulb and maybe the train indicators too. I will probably blankout the headlight engine number boards and use unlit decals on those. Decals are a real problem that small, trying to get the lighting to show correctly and not bleed through.

The search continues for either a 16K RPM motor or looking into making a new primary gear reduction tower to cut the gear ration to a more reasonable 23:1, not the factory delivered 47:1.

May 29, 2007

The three screws that hold the boiler top on are located under the steam turret, main steam dome, and superheater on the end of the smokebox. The front two are easy to remove, just grip gently and life the domes off. The superheater casting is buried under about five pipes that must be carefully disconnected and pulled back. Also disconnect the hot water pipes from the hot water pump at the bottom of the smokebox. There are two screws located under the ladders of the cab. To reach them you must remove the front coupler and pilot and front silver panel of the cab front. This part soudns worse than it is. The cab is still attached by the wire bundle for the five LEDs in the cab. So be careful not to break any of them unless you are going to relight the engine.

Once the boiler top is loose, you can remove it leaving the cab, lower portion of the boiler, and running gear. Three screws hold the top of the boiler weight to the bottom one. Remove these three screws. The wiring for the motor and the lighting run along the top of the top boiler weight.

I have not removed the top weight on my engine yet, but was able to see everything I needed to before the "open heart" to replace either the motor or the main gearbox. I will carefully remove the wires by unsoldering them from the motoro and cutting the factory lighting wires, as I will replace the lighting system.

Once the wires are clear, the top boiler weight should come off easily. The motor is in the firebox and just forward of the fixed cylinders is the main gear tower. I am not sure how the gear tower is secured to the lower boiler and frame drive shafts to the wheels. (I find this out later... and it's a pain!)

At any rate, there is the basics of how to get into one of these engines.

Update

Sept 11, 2008

During this year I set up the first two IMRC AC's 4279 and 4233. There was a lot of tinkering done to them.

SP 4279 - Mk-1

|

| More detailed view of the right side of SP 4279 before I put a crew in her. |

SP 4279 was the first engine that I received and installed DCC in. I have opened it up and intalled a 11.6K RPM Faulhaber motor in it. The engine can not make 45 MPH, However, there is still too much gear noise.

I have used this engine as my test bed for changing out the lead truck spring to a "whisker" type spring made from 0.03" phosphor-bronze wire.

I also filed a slot in the No. 1 driver bearing in the frame to accept a spring package to increase the down force on the No. 1 driver in an attempt to fix the derailing problems. This solution did work but it was not easy to do.

SP 4233 - Mk-1

|

| Left side of SP 4233 with moderate weathering on the running gear. |

SP 4233 was the second engine that I stared modifying. This engine was opened up and after diving into the deepest innards of the engine, I swapped the first two gears in the primary gear tower to double the speed of the drive and cut the torque in half. This engine also now develops 45 MPH as it's max speed, while keeping the nose down to acceptable levels. I have not regauged the engine as yet.

Conclusion, I can modify the IM AC's to run acceptably. However I am going to wait on rebuilding any more until we see waht IM is getting in their 2nd run and if the problems that I have been discussed are fixed.

Arrival of the Mk-2s around November 2009

I posted to several Yahoo Groups a photo essay of my rebuilding of the Mk-2 IMRC AC-12s with the Mashima 1833 motors. I am including it here for completeness. Click any of the photos to get a larger view of the image.

Photo Essay of Remotoring and Detailing an IMRC AC-12 in 2009

|

| Modifications to the left side of the engine |

|

| Modifications to the right side of the engine |

|

| Detailed view of piping modifications on the left side of the steam turret. |

|

| Removing the Steam Turret screw. |

|

| Removing screw from Steam Dome |

|

| Modifications to the right side of the smokebox |

|

| Modifications to the left side and rear of the smoke box |

|

| Unmount the three pipes connected to the top of the FWH |

|

| Remove FWH from the top of the smokebox |

|

| Remove FWH screw |

|

| Removing the handrails and rods from cabside |

|

| Cutting air pump pipes to make removing the boiler shell easier. |

|

| Lift smokebox end of boiler shell off of engine. |

|

| Lifting the left side of the cab and boiler shell off of the engine |

|

| Removed the ladders for ease of working on the engine |

|

| Watch the wiring! |

|

| The simplified wiring in the cab and brakeman installed |

|

| Mark the wires so you can reconnect them later - Love IMRC using all black wiring! |

|

| Removing stock motor |

|

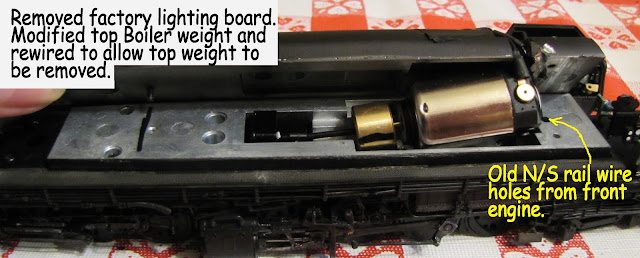

| Modifications to boiler weight |

|

| Modifications to top boiler weight |

Crew sculpting for the 4255.

|

| Crew in the front of SP 4255 |

|

| Crew installation |

|

| Engineer's repositioning |

I originally posted these photos in December 2009.

Overview of Modifications

I traded out two Mk-2 engines and bought one new Mk-2. Also joining this group of engines was a customer's Mk-2 engine as well. I'm calling my upgrades a Mk-2a version. Let's follow all four of these Mk-2a engines as I modified them and put them into service.

|

| SP 4255 leads a freight down grade into Caliente. |

All four engines received a Mashima 1833 can motor and upgraded LED lighting. Decalling was done using San Juan Decals (out-of-production, as of 2016).

Service History of the Four IMRC Mk-2a AC-12s at LMRC 2009-2014

|

| Rebuilt MK-2a engines SP 4255 and SP 4230 preparing for trips out of Mojave in January 2010 |

I will list below the basic detailing unique to each engine and how the engine faired in service at the club. I often would run at the club a couple times a week, often these engine would work as helpers in freight trains I would run, and about every 2-3 months they would make a couple of trips over the railroad during the 1950s Timetable/Train Order (TT/TO) sessions. So it would be safe to say that these engines worked an average of about 3-4 laps per month during the time they were in service.

SP 4202 - Mk-2a

|

| SP 4202 rolls into Bealville, CA. in early 2010. |

The 4202 is a fun engine because I backdated this "AC-12" to be the earlier AC-8 with the doors on the front of the engine instead of the three screened over panels. I salvaged this door detail from some brass parts and filled and sanded over the extra width of the AC-12 screens.

|

| SP 4202 leads the fan trip through Soledad Canyon. - Photo from Eddie Sims Collection |

I finished SP 4202 as a nice clean, freshly shopped engine as it appeared during its trip over Tehachapi pass on a wild flower excursion in 1953.

|

| Of course the 4202 wasn't always that clean... Photo from Eddie Sims Collection |

The IMRC model of SP 4202 is I think the shortest lived Mk-2 of the four. It failed in September 2010 with some sort of a cracked gear and binding issue. I have not had the time to take the 6+ hours to open it up and tear into all of the internal gear boxes to find where the problem is.

Time in service ~ 18 months. - Plan to return to service after heavy shopping to repair gear train damage at unknown date.

SP 4230 - Mk-2a

|

| SP 4230 helping a westward freight at Bealville |

SP 4230 was finished with the large SP tender lettering and a rather clean boiler. The running gear was weathered with some medium gray washes and drybrushing to highlight the details. The sides of the cistern was weathered to simulate the dirt that usually sticks to the condensation because of the cooler water in the tank, while the fuel bunker is heated and doesn't have any condensation for dirt to stick to.

The IMRC model of SP 4230 lasted until 2014 when it bound up near Kern Jct with some sort of cracked gear or bind. Further inspection revealed that all the drivers were badly out of true and wobbling over one flange width. The bind would lock the engine up at the same point every driver rotation, but would allow reverse running.

Time in service ~ 5 years. - In need of major shopping, new drivers from IMRC.

SP 4249 - Mk-2a

|

| SP 4249 helps a freight eastward into the west end of Caliente. |

The 4249 was finished per photos that showed it was assigned to one of the mountain divisions that did not continue past 1947 with the large "SOUTHERN PACIFIC" on the tender sides.

The IMRC model of SP 4249 lasted in service until 2013 when it suffered a slipped drive shaft at the flywheel and the Mashima motor. This actually shouldn't be hard to repair with some LockTite on the motor shaft and flywheel. Time to repair should be about 3 hours.

Time in service ~ 4 years. - Planned to return to service after light repairs

SP 4255 - Mk-2a

|

| My SP 4255 is probably the most photographed of any of the Mk-2 IMRC engines I did in this batch. |

The SP 4255 is one of my favorite rebuilt IMRC engines. On this engine I tried to replicate how I see many of the firemen in historical photos. We often see their backs as they crane their backs over the armrest to look back to the stack, checking how their doing on the firing valves. This really is the only way to be able to see back out of the cab while still being able to have your hands on the firing and atomizer controls.

The IMRC model of SP 4255 was found to have the same wear on the drivers as the SP 4230, which show as a wobble out of true of over a flange width in gauge. Engine withdrawn from regular service in 2015 and stored serviceable if needed until repairs could be made.

Time in service ~ 5 years. - Planned to replace all drivers with new sets from IMRC at future date to return to full service.

The engine stolen in late 2015 and recovered in early 2016. Unfortunately the 4255 was badly damaged while stolen. My revised plans for this engine now are unknown as now I'll have to repair all the detail and finish damage as well.

Disposition & Notes

All other original club members planning to purchase IMRC Mk-1 or Mk-2 ACs canceled orders in 2007. Two additional Mk-2s were acquired in 2009, but never rebuilt to Mk-2a standards to enter service. Their future disposition unknown as of Jan 2017.

SP 4233 - Mk-1b

|

| SP 4233 stored awaiting deposition |

The 4233 is currently awaiting new drivers to upgrade it to Mk-2a level, honestly I'm not sure it's going to be worth it.

SP 4279 - Mk-1a

|

| SP 4279 now is a static display model at the Bakersfield Roundhouse at La Mesa Model Railroad Club. |

The Mk-1 4279 has been retired and used as a parts engine to keep the other Mk-2s going. It was the testbed for modifications, but it also gave up parts to repair other models that took the worst of the abuse, including having the tender drawbar bent in half, lost eccentric rod screw, melted driver core (short circuit between booster sections!), and lost side rod crankpin.

There's a series of photographs taken from the top of the water tank near the roundhouse that shows what I believe to be the real 4279 on one of the "Garden Tracks" getting replacement flues and superheater tubes installed and the tender resting on the other side of the roundhouse area for the work to be finished.

|

| SP 4279's tender now lives on the other side of the turntable from the engine. |

I plan to finish the static diorama with the 4279 with a superheater tube replacement scene going on, and a "monkey deck" level cart behind the engine. The tender of the 4279 now resides on the other side of the turntable.

Closing Thoughts

The IMRC Mk-1s and Mk-2s are very beautifully detailed models. Unfortunately they don't have the same tractive effort as WSM/KTM or Balboa/KTM brass models. It also seems that they don't hold up to regular service nearly as well as the brass models, which usually can last 30+ years in regular service if properly cared for.

One of the major shortcomings of the IMRC design is the 4-6 hours required to get down into the main gear tower and stripping the whole engine down. KTM built brass models only require about 20 minutes to completely disassemble the drive train. This is a major issue to keeping these engines in regular service as shown by the failure of the SP 4202 and tracking down the failure in the SP 4230.

Another on going concern is that the Mk-2s had very stiff pickup wipers on the backs of the drivers, this tended to load the motors very hard. After about 2 hours of running (one lap at LMRC) the boiler shells would be hot to the touch, estimated about 120-130F, which means that the boiler weights inside the engine must have been more like 150-170F, and I don't even want to think about how hot the poor motors were inside there, sandwiched between the two weights. The engines would also run noticeably slower after 3 or so hours of running which means that the motors were loosing power because they're overheating.

Trying to bend back the wipers is not an easy chore on the Mk-2s. I really do not like the solution some people came up with on the forums of simply cutting off the driver contacts to solve the issue. I don't trust the all wheel tender pickups enough to do that. I hear that the Mk-3s have the pickup tension significantly reduced. The motor's enclosure in the boiler weights still concerns me a bit with heat build up.

I've not had a chance to closely examine the new Mk-3 IMRC AC's but short of major retooling of these models I don't see the Mk-3 changes really changing my conclusion of how these models hold up. For the average person that wants a pretty model the IMRC AC's are fine, but for serious operations over many years on grades with tonnage trains (16-18 cars per engine on 2.3% grades) brass models are still really the only option.

(Edit: I did have my first experience with a Mk-3 AC-10 in which my friend and I were repairing some damage, SP 4239, a Mk-3 IMRC AC-10 (Part 1) Damage Control)

I hope you all enjoyed my revised page on these models.

Jason Hill

Related Links:

SP 4239, a Mk-3 IMRC AC-10 (Part 1) Damage Control

Modeling Consists - the Owl (Part 1) from WW2 to Korea

Modeling Consists - the SP Mail Trains, Nos.55/56, the Tehachapi Mail

La Mesa Model Railroad Club - Prototype 1950s Operating Sessions Overview

Home

I returned two first run engines for second run replacements.

ReplyDeleteMajor problems. Unfortunately they had been stored on receipt. First few times they ran, no issues, second time about 10 minutes before decoder and other issues.

Didn't like it, but since I didn't have the time to upgrade/repair, paid (bad move on IMRCs part. Left a real bad taste in my mouth. Should have been a warranty issue.) Paid to get mechanical upgrades to 3rd run. Included note about valve gear issue on one.. Decoder allegedly fine.

WRONG. Valve gear issue NOT corrected, but really not all that noticeable. However decoders almost immediately failed.

Back again. "I don't care how you do it, but I want two sound engines that work, and I don't want to pay anymore."

These two finally work well mechanically and have the Lok-Sound decoder. No real decoder problems except getting the decoders to sound more or less alike. Mechanically, well the valve gear issue is still there, after 2 factory test runs and factory repair/upgrade.

As noted they can't pull as much as I would like on a grade on my club layout. They stall with a train my two Athearn Mountains or one Challenger have no problems with. If I swap one out and add a Genesis A-B-B-A helper set, the train flys up the grade.

So while I am more or less satiafied, I'm not likely to go back top IMRC for engines for a while if ever.

CAn you go in to more detaile on your weathering methods?

Thanks a million for posting how to disassemble the IMRC AC-12 without destroying it. Just aquired one myself off of eBay, blue label version. The mechanism seems to be ok along with the motor. The headlight is a joke along with the older Tsunami sound decoder. I plan to gut the antiquated Tsunami sound decoder and replace it with a Tsunami2, replace the speakers in the tender, fix that lyricist headlight with a more realistic LED shade of white, and install orange LED in the cab for a firebox gate flicker effect, along with red and yellow LEDs to cast a glow upon the lead truck just below the firebox. Oh, I like your adding the engineer, fireman, and breakman in the cab. Nice human touch. Truly appreciate all your work and thanks for posting those incredible photos on how not to destroy this otherwise incredible model.

ReplyDeleteThank you for posting this information about the intermountain cab forwards. I know that one of the runs had green labels on the boxes and another had white, but do not know which color applies to each run. Do you have the information on which color was used for the three different runs?

ReplyDeleteHello William,

DeleteI think it was white (1st), blue (2nd), and I don't have a 3rd run... so that could be green. Honestly, I'd have to go dig out the boxes and look to see what I have.

Thanks again for the information. I have one with the white labels that I was pretty sure is the first run.

Delete